One way to get a signal would be to use the p connection on the 140 amp cs144 alternators sflp plug. Calibration and adjustment the tachometer is factory calibrated to 3 full scale accuracy.

How To Install A Tachometer 8 Steps With Pictures

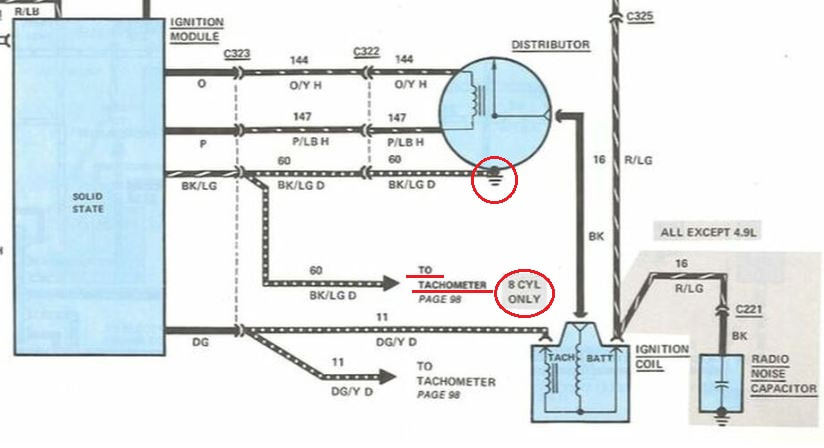

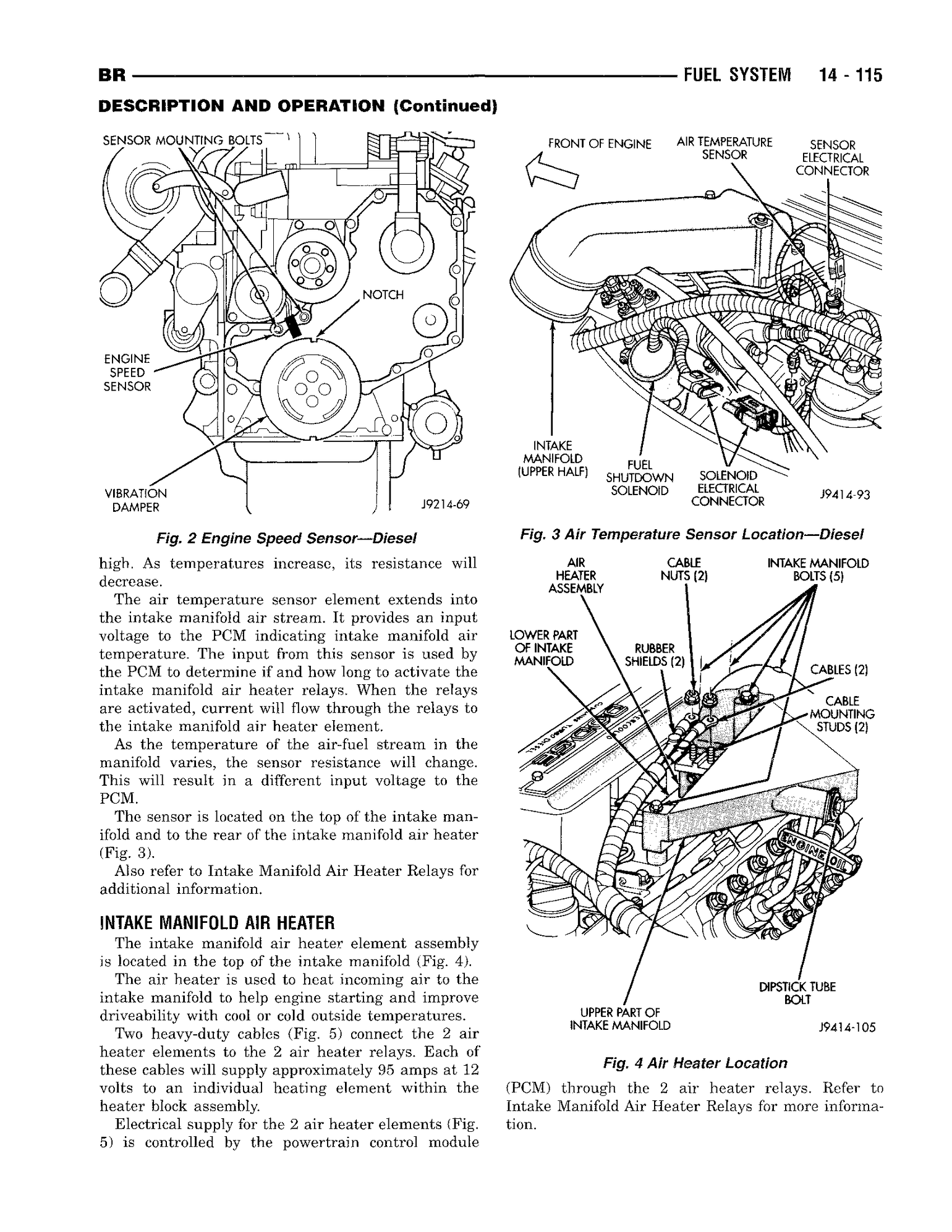

Diesel tachometer wiring diagram. The probe trigger will. Buy your diesel conversion parts here. Wire alongside other wires. If not check wiring. Because diesel engines dont have a coil to provide an ignition signal for the tachometer to measure we are forced to find other ways to get a signal thats proportional to engine rpm. If the tachometer needle goes to zero when powered up but does not respond when the engine is started there is no signal to the green wire.

Here well do just that on with a dodge gen 1 and 2 cummins alternator. Gasoline engines or with diesel engines and can be used with most ignition coils. Learn how to install a signal wire on your diesel alternator. Check to ensure that the green wire is hooked to the proper location for a valid signal. If the tachometer needle doesnt go to zero when powered up the tachometer is not grounded properly or. When wiring is complete connect power.

T urn key ìonî ó tachometer pointer should move to ìzeroî. We recommend using a 3 amp automotive type fuse. Start engine and check gauge for proper operation of tachometer. Provision has been made for finer adjustment if. The diesel tach adapter dta is provided with a probe assembly that is to be strapped to the vehicles alternator. As a safety precaution the 12v terminal of this product should be fused before connecting to the 12v ignition switch.

These instructions describe the installation wiring calibration and operation of all vdo programmable tachometers. Each tachometers analog display clearly shows the number of revolutions per minute and the lcd display shows the accumulated engine hours.