Materials used in the construction of the loop are important. First remember that the loop is an integral part of the detector electronic circuitry.

Loop Detector Traffic Vehicle Detectors

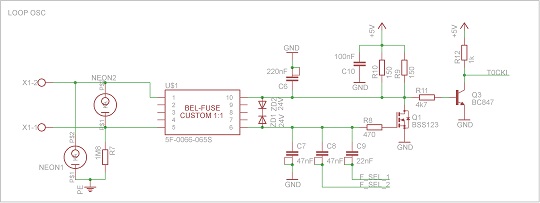

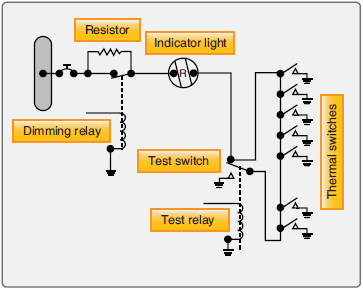

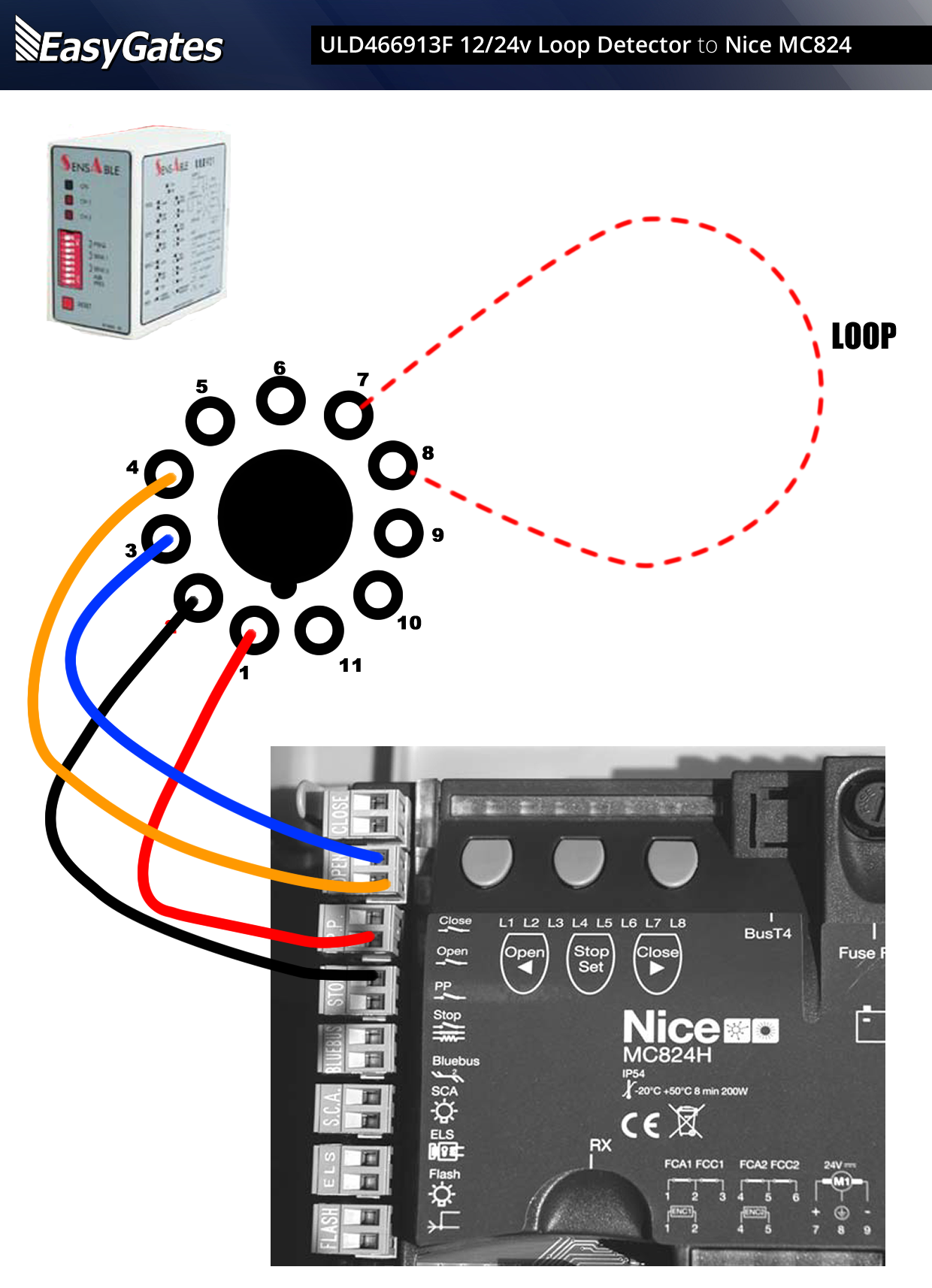

Loop detector wiring diagram. Collection of loop detector wiring diagram. The home run to the pull box shall be requirements of imsa. We the loop detector manufacturers entrust you with making a very important electronic part of our loop detector. It reveals the parts of the circuit as simplified forms as well as the power and signal connections in between the devices. The loop wire should be 16 gage stranded. Loops with same one or two turns conductor cable no.

Do not leave a car on the loop or any other metallic objects when it is calibrating. The wire gauge is not critical to proper operation of the loop detector. 14 stranded single conductor wire which meet the requriements of imsa. The wire should maintain its integrity under the pavement stress. A wiring diagram is a streamlined traditional photographic representation of an electric circuit. Pd132 loop detector specificationver100 4 use and operational on powering the pd 132 loop detector it will automatically calibrate.

A wiring diagram is a streamlined conventional pictorial representation of an electrical circuit. Assortment of loop detector wiring diagram. Since asphalt is more flexible than concrete it is recommended that a heavier gauge wire be used for loop installations in asphalt. It shows the components of the circuit as streamlined forms and the power as well as signal links between the gadgets. Loop wire above and below number indicates wired in series detector no. When correct it will show 2 leds.

A wiring diagram normally gives details concerning the loved one setting and setup of gadgets as well as terminals on the gadgets to help in building or servicing the tool.