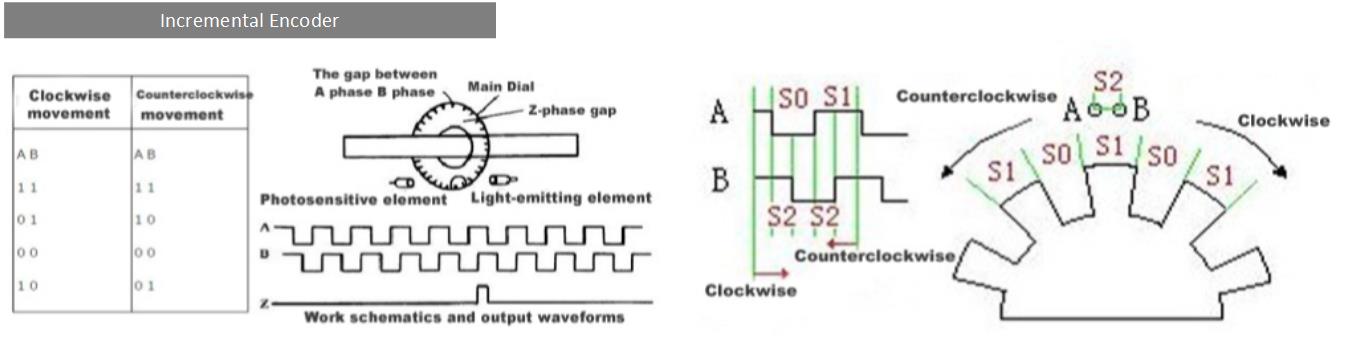

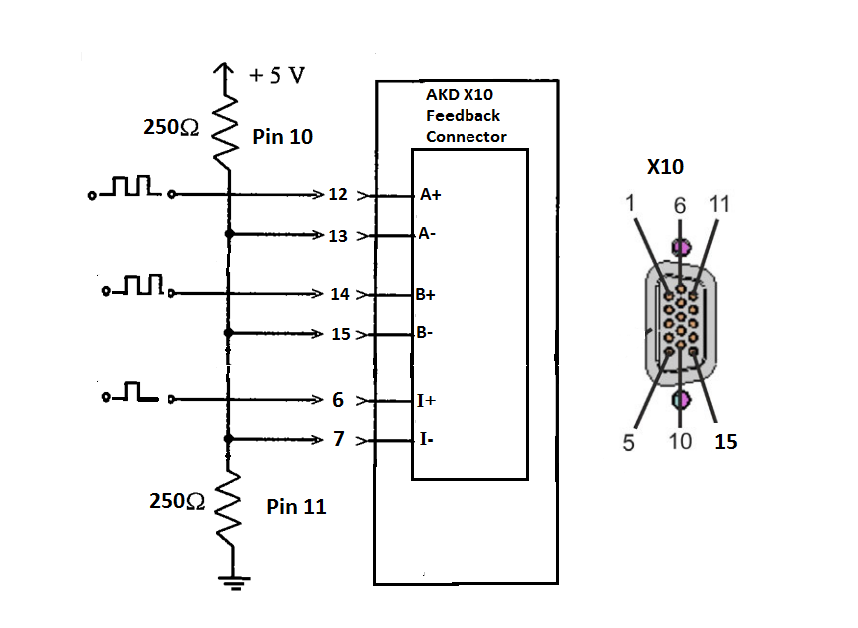

Multi channel differential encoder wiring with commutation tracks can have up to 14 wires and miswiring can result in signal issues such as deformed pulses low signal amplitude and shorted connections. The incremental encoders emit electrical pulses that can be used to determine position and cal culate speed.

Incremental Encoder An Overview Sciencedirect Topics

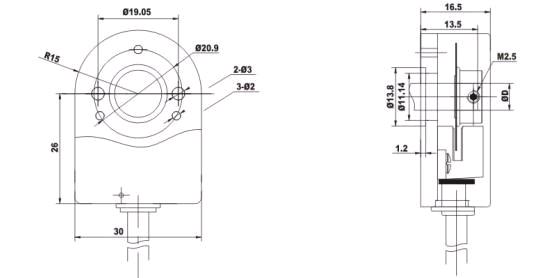

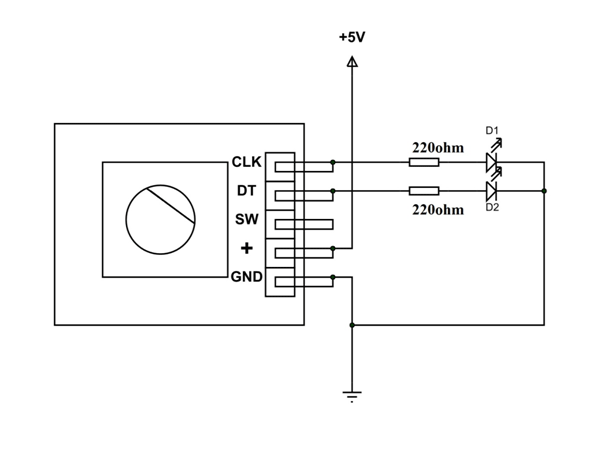

Incremental encoder wiring diagram. A single channel encoder often called a tachometer is normally used in systems that rotate in one direction only and require simple position and velocity information. General information channel a channel b single evaluation double evaluation quadruple evaluation encoder basics. Example encoder with hollow shaftfig. Basically this step is the minimum amount you can rotate the encoder to register any change. All notes and tables referred to can be found on the back of this page. Incremental encoders are available in two basic output types single channel and quadrature.

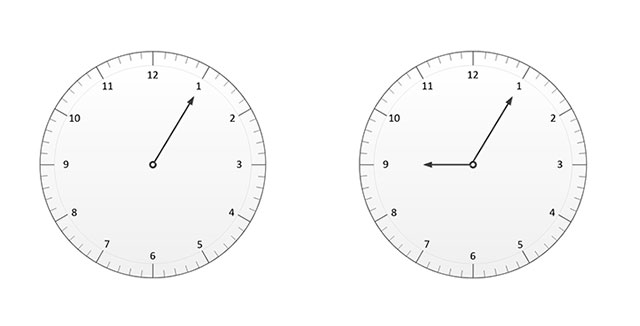

Quadrature encoders have dual channels a and b phased 90 electrical degrees apart. Connect the red wire of the servo motor to the external 5v supply the blackbrown wire to ground and the orangeyellow wire to the pwm enabled pin 9. Refer to the wiring diagrams and pinout and phasing tables for specific information on each option. As the wiring diagram shows youll need a servo motor. Ato encoder is an incremental rotary encoder with 600 ppr npn output solid shaft and ab phase. For bidirectional operation of the encoder proper phasing of the two output channels is important.

To be increased electronically to 5000 or 10000 pulses per revolution see diagram below. Each method of wiring has its advantages and drawbacks. To illustrate other incremental encoders have three channels of data transmissiona b and z for indexing to a setpoint. In order to observe rotary encoder pulse output intuitively ato use a plc with high speed counter. A rotary encoder rt is a device that you can rotate infinitely. Output signals of incremental encoders this enables the resolution of a two channel encoder with 2500 lines per rev.

The angular velocity of a shaft. Hs35 express encoders items highlighted with are standard express. Encoder wiring schemes can be unique to each encoder and one should follow the diagram or pinout designated on the encoder datasheet. On most rotary encoders when you rotate them you will feel a bump known as steps and most rts have about 12 of these per rotation some have 24 or more. Example encoder with solid shaft 42 operating principle encoders detect rotational movements eg. 41 device overview fig.

Wiring diagrams are shown for zone 1 and zone 2 applications. Phase a channel typically leads phase b channel for clockwise shaft rotation. Such an encoder with differential wiring has six wires total and each channels wire pairs feed twin signals to a controller that discards errors to clean the input. Hs35 incremental ordering options for assistance call 800 350 2727 use this diagram working from left to right to construct your model number example.